Taking an Idea for a Walk

title stolen from the MOMA show “Taking a Thread for a Walk” which was stolen from Paul Klee who described a line as “a dot that went for a walk.”

Hi all,

I am once again reposting a blog post I wrote for Groundweave.com based on a presentation I did for my guild. I guess I was a little optimistic that I would get around to writing entirely different posts here, but the topic might interest you. I hope so!

I was asked sometime this spring whether I would do a presentation for my guild on my design process. I love my guild, so I said yes, thinking to myself, “hmmm, what is my design process?”

SO, under deadline, I had to dig in and think about how I (possibly we) go about creating and executing designs for woven cloth.

After mulling for a while I was able to break it down into 5 (pretty basic) ideas. The alchemy I think is in how these elements come together, in what proportions, and how they affect one another. I think of the mix as “the cauldron of creativity”.

The components are:

- Necessity

- Materials

- Inspiration

- Intuition

- Exploration

I am not moved to express abstract ideas through weaving. I don’t really believe (like Rothko did about his painting) that there can be some kind of divine communication through my weaving. What I do firmly believe in is the power of good design. That beautiful and useful objects bring joy, and that good design is hard and elusive. It is a process of bringing function, form, materials, trends and inspiration into a designer’s personal aesthetic to generate something interesting and good.

Many times the process starts with necessity. And when I say “necessity” I just mean that there is a need or a desire for something, whether it is a set of towels for gifts, a request from someone for a pattern or an article, a desire to weave something for a weaving conference, etc. However, necessity doesn’t have to come first. A new yarn could be the spark that sets the idea in motion. The order of the elements changes often.

Materials are a huge part of the process. They can be the inspiration for a project, ex. I saw a piece woven of horsehair at the Vävstuga weaving school. I immediately found a source of horsehair with no idea what I would do with it. It wasn’t until I had the the horsehair in one hand and a book of Agnes Martin’s work in the other that I had a vision of what I wanted to do.

Horsehair sketches inspired by Agnes Martin painting (lower left)

But materials can also be stumbling blocks. For example, I want to weave X, but I only have a 4-shaft loom or I have a vision for a fabric, but can’t get the grist of wool I need in the colors I want. Part of good design (I have been told) is being able to use those stumbling blocks as doors to further creativity. My mentor Ute Bargmann said it most succinctly when she said “Use your brain, not your shafts!”

Obviously inspiration can come from anywhere. I read about a weaver who stalked a woman on the streets of Paris until she could get close enough to create a draft the fabric of the woman’s jacket. I don’t often try to translate landscapes that inspire me directly into fabric, but I do find myself responding to my environment in my weaving. When I am in the bright, high desert I choose much brighter colors to weave with than I do when I am in the grey, green and lichen-y environs of Western MA where I lean toward more natural and heathery colors. When I am at a loss, I often turn to my library for inspiration. Simply looking at my books on Jute Rugs from India, Textiles from the Andes, or my Knoll Textile book can spark something.

Intuition is mysterious because it is impossible to know how much comes from some innate sense and how much comes from experience. It seems to be a combination of experience and imagination. I think that it is great to trust your intuition at the start of a project because it allows you to forge ahead into unknown territory, but then one has to be willing to tweak or change direction as you see where your intuition has taken you.

Exploration can be the beginning – I need to weave something to help me learn more about double weave. Or it may come later in the process, i.e. I need to weave a scarf (necessity), using this lovely wool (material), that reminds me of the scarf my friend got in Scotland (inspiration). What structure and sett will help me create a soft, stable fabric like my friend’s scarf (exploration). Exploration can happen in the drafting process or on the loom. It can be finding the ideal beat for the structure/fiber/sett you’re working with – or tweaking a color if things are looking boring – or changing the tie-up to keep things interesting – or simply working out the possibilities of a threading. I have an ongoing discussion with Véronique Perrot about on-computer vs on-loom explorations. She maintains that you can’t really decide on colors until you’re at the loom, and that it is a good practice because it keeps the weaving process from getting boring. I tend to work out all the details and variations before putting a project on the loom. I only veer or tweak if what I envisioned isn’t really coming to fruition.

I thought it might be helpful to walk through a recent (last couple of years) project that I have been working on. By breaking down my process for this post, I don’t mean to imply that there is some kind of master plan that I follow. I had to really think about individual projects to come up with common elements. So I want to be clear that this is a murky business for me. Sometimes I have an idea in the middle of the night that I “have to weave”, and sometimes I sit at the computer drafting for hours trying to come up with something that I think I will like. I often tell classes that when I look at an array of things I have woven, I would give myself an optimistic 20% success rate. I don’t mean that 80% of the things I weave are total failures, but rather that of the things I weave, I fully like the final product about 20% of the time. The idea is good, the weaving (sett/beat/selvedges) is good, the finishing is good, the proportions are right, the colors are interesting and I wouldn’t mind having it in my house. The rest go from bad to okay to pretty nice, etc. I don’t mind failure, which is good for creativity, but I am trying to bring my success rate up a bit, mainly because I am slower than I used to be, so I need to increase my success rate just to get the same number of hits:)). But let’s talk through the process of one idea.

The Baby Blanket

A great nephew was born, and a neighbor who stopped by the Working Weaver’s Studio Trail told me “hint, hint” that they were expecting two new grand babies. (necessity)

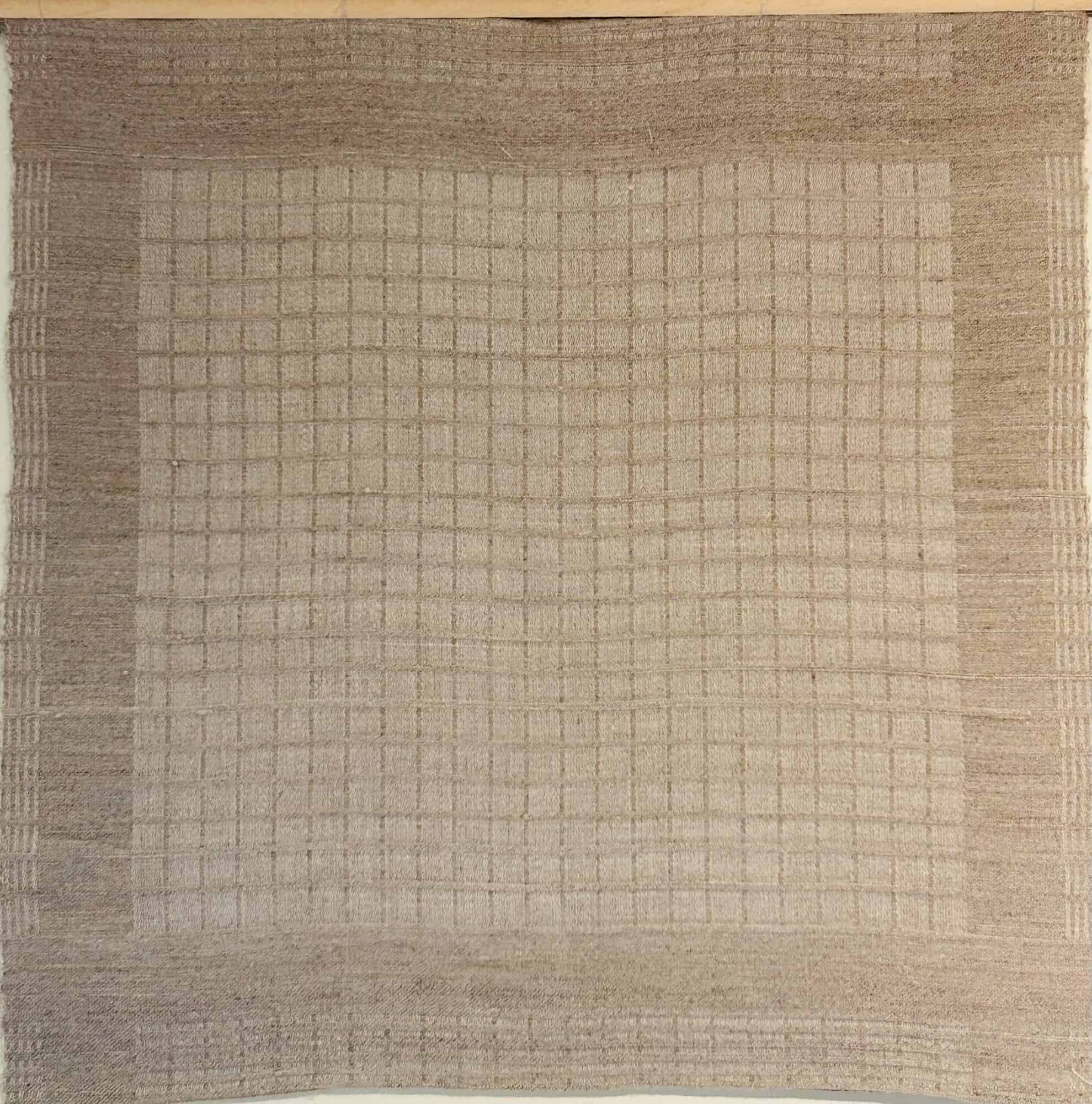

I had always wanted to figure out a way to get a baby blanket that was as soft as a knitted blanket. My mind kept going to super soft yarns like merino and baby alpaca, but I knew that new parents would not thank me for a luxury blanket that they couldn’t wash. And I did have a couple cones of Henry’s Attic Monte Cristo boucle cotton on my shelf (material). I really wanted to use the Monte Cristo because it is so soft, and affordable. The down side was that it is only available in Natural. So, in order to get a colorful and soft baby blanket, I decided that I would use some variation of double weave.

I have woven a lot of double weave, but didn’t want the firmness that comes with a lot of block double weaves. I loved the texture of the few things that I had woven in stitched double cloth, and knew that for a baby blanket, I didn’t want to stuff the layers (often called matelassé) or have a one-sided blanket (true of a lot of piqué). So I went the stitched double cloth route, and started drafting with the help of my friends:

Piqué: Plain and Patterned Donna Sullivan

Mastering Weave Structures Sharon Alderman

Designing Stitched Double Cloth (Best of Weavers: The Magic of Double Weave) Doramay Keasbey

Doubleweave revised and expanded Jennifer Moore

Doubleweave on Four to Eight Shafts Ursina Arn-Grishott

I started with intuitive notions about the yarns, the structure and the sett, but learned, changed and tweaked throughout the process. I used some photos as color inspiration.

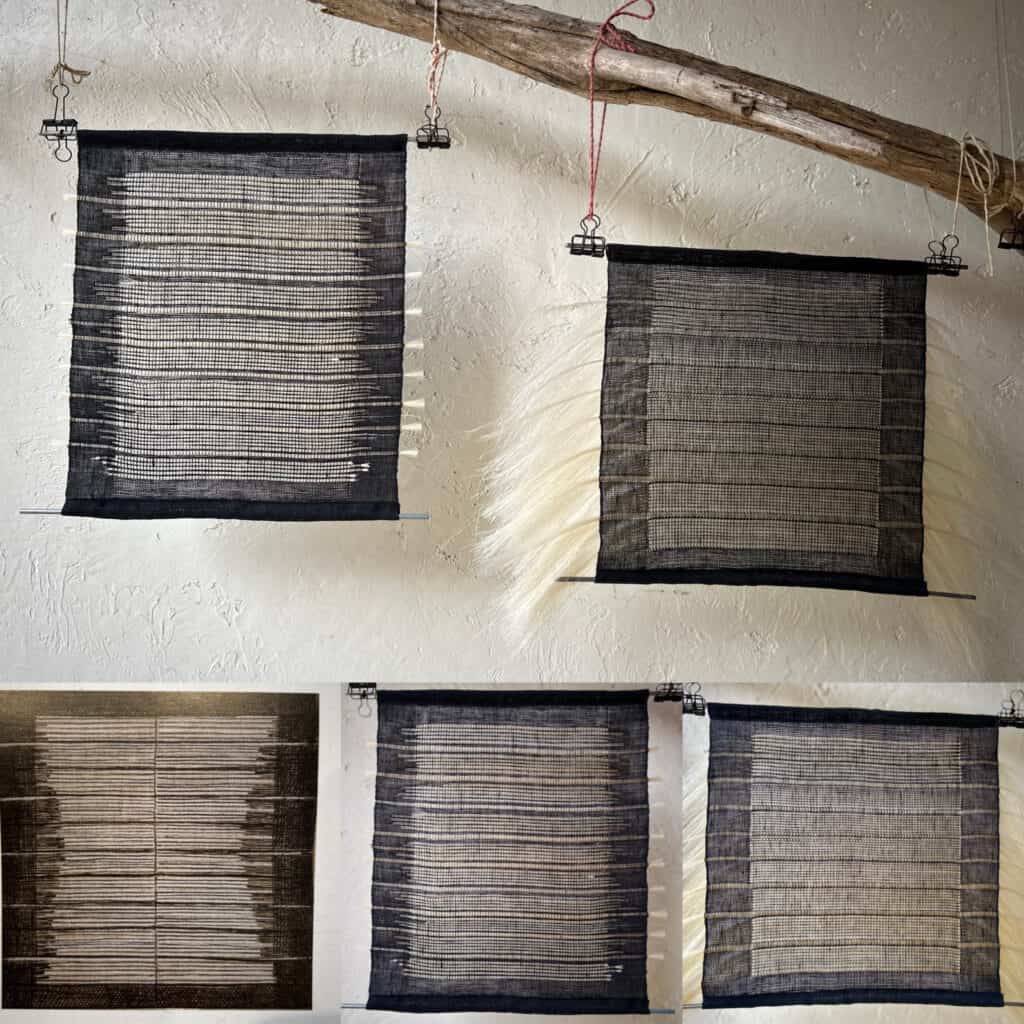

First Try – cottolin and Monte Cristo stroller blankets

I wasn’t happy with my boring horizontal stitchers, so I tried again using color inspiration from a photo of a child’s nursery.

2nd try, stitchers in straight twill order. I liked the colors but wanted a more exciting stitcher pattern.

I drafted and wove many prototypes. (exploration)

3rd try – I got better stitchers and really liked the desert-y colors. I was close.

Final – These two versions are two different treadling sequences. One was better in terms of stitcher density, but very arduous to treadle.

The main challenges were:

- How to get the most possibilities for patterned stitching on 8 shafts (notice how I go from straight, horizontal stitchers to diagonals to diamonds).

- How to manage the ratio of thick and thin threads.

- How to make the stitching pattern visible without making the fabric too stiff.

- How to draft the treadling so as not to lose my mind.

It took me an embarrassing whole warp to learn that to get the stitcher pattern on the colorful side, I needed to draft the Monte Cristo side to that pattern. When I say that my “ library friends” helped me, don’t blame them for my impatient skimming habits!

I continued to use Monte Cristo as the fluffy side, but have done a blanket using Jane Stafford’s Cotton Cloud (which comes in colors!) as an alternative. I stuck with Venne, Brassard Cottolin and Gist Cotton Linen (mixed willy-nilly for the colors I wanted) as my thin layer because I have a lot of it in colors I like, but cotton might be a bit softer and accentuate the “quilted” effect more.

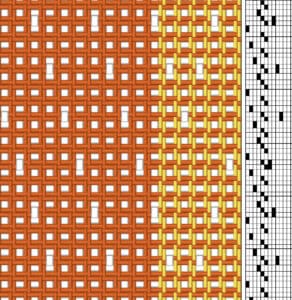

I started with a 3:1 ratio of thin to thick. 24 for the cottolin and 8 for Monte Cristo with the thin threaded in a 3/3 twill and the thick threaded to plain weave. That was my “duh!” moment when I realized that the thick threading was the determiner of the stitching pattern on the thin side. I then moved to a 2:1 ratio, 18 for thin and 9 for thick with thick threaded to twill and thin threaded to plain weave. I liked this texture, but realized that most weavers don’t have 9-dent reeds. So for my final version and after working with Jane Stafford and her alarmingly open setts, I moved to 2:1 ratio of 16 for thin and 8 for thick with thin threaded to plain weave and thick threaded to a point twill. I know this sounds riskily loose, but the stitching takes up space and I wanted a super cuddly result.

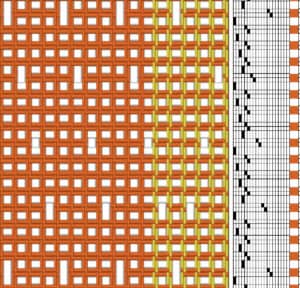

I wanted a series of diamonds across the warp, so I used an extended point threading for the thick warp and plain weave for the thin. As you can see in the draft. The thins are threaded in pairs on 4 shafts, it could have been threaded on 2 shafts, but I didn’t want to move heddles so I threaded it on 4 shafts:)).

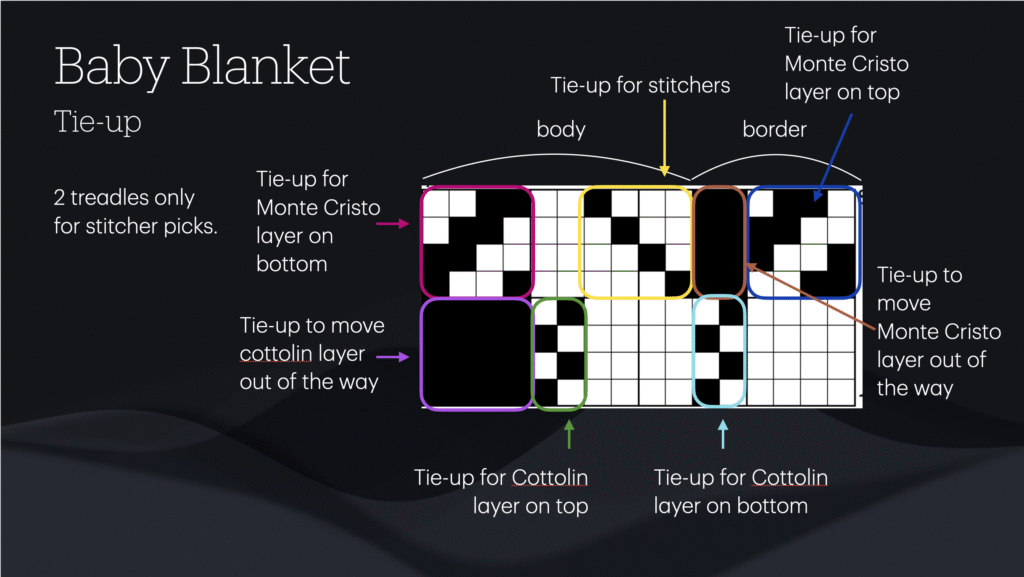

![]()

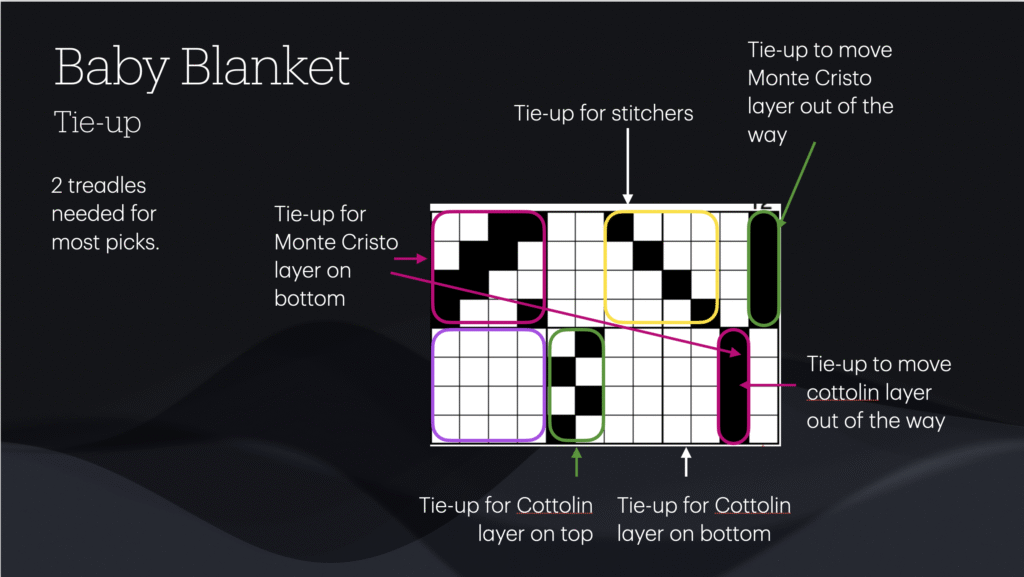

This is the standard tie-up for the body and the borders – since most 8-shaft looms don’t have 16 treadles, I tied up for border 1, re-tied for body and then re-tied again for border 2. This tie-up is still technically a skeleton because you have to step on 2 treadles for the stitcher picks.

But the whole thing can be reduced to even more of a skeleton on 12 treadles as seen in the next pic.

For the final warp, I wove a version in which I placed the stitchers every 8th & 9th pick (first pic) which I think was a perfect interval, but that was a real “pat your head/rub your stomach” treadling sequence in which the stitchers didn’t fall at the same place in the thick treadling sequence,

so I adjusted it for ease of treadling. For the final version I placed the stitchers every 11th &12th pick (pic below).

So the story of this process involved a request from a neighbor (necessity), materials on hand, inspiration from books, previous projects and an adorable wee grand nephew who appeared on the scene, an intuition of how to start and then a lot of exploration and experimentation to arrive at the “final” iteration. When I say “final” I should say final-ish because I have a few more ideas about how to make the ultimate, final version, and there is a new wee fellow on the scene who needs a cozy blanket. The Bouncy Baby Blanket Pattern is available at Plainweave on Etsy if you want the full story!

Terri

I would so love to be able to weave this baby blankie as my daughter is expecting her first baby in May but unfortunately as I’m across The Pond in the UK the Monte Cristo & the Jane Stafford Cloud Cotton yarn is unavailable here (postage is extortionate!) can you suggest a substitute perhaps?

Best regards

Terri

Elisabeth Hill

Hi Terri,

I hear ya! The tariffs are causing all kinds of trouble for those of us who have been getting yarn from all over the globe. I don’t know if you’ve ever looked at Colourmart yarns. They are based in the UK I believe and get fantastic mill ends that they resell. Because the yarns change all the time, I find them useful for specific projects rather than stash building. You have to keep checking to see if they have something in the fiber/grist range you need. In the case of Monte Cristo – look for a soft textured cotton in the area of 1,200 yards per pound. I hope that helps. And big congrats on the new baby.

Terri

Thankyou muchly for the advice Lisa I shall go take a look @ Colourmart yarns – I haven’t heard of them before!👍

Best regards

Terri